Opportunity

Opportunity

With R&D Tax Credits now being permanent, the timing has never been better for the Food & Beverage Industry to take advantage of these often-substantial credits:

-

- The R&D Tax Credit provides a dollar for dollar reduction in a company’s tax liability;

- In addition to current year tax savings, the credit can generate a refund of taxes previously paid for open tax years (generally the prior three years); and

- The credit can be used as a carry-back for one year and a carry-forward for 20 years if your company does not have immediate utilization for these credits.

If this isn’t convincing enough, the rules for calculating and claiming R&D Tax Credits have recently become more tax payer friendly. So, if your company has looked into R&D Tax Credits in the past but was scared away by stringent qualification standards or the difficulty of the calculation itself, these recent changes might make you take another look:

-

- The Alternative Simplified Credit (ASC) method can now be elected on amended returns instead of only on original-filed returns. Introduced in 2006, the ASC is equal to 14% of total qualified research expenses that exceed 50% of the average qualified research expenses for the three preceding taxable years. This method is less complicated than the “regular credit” calculation created in 1981 and does not rely on antiquated data.

- The definition of prototypes has been more clearly defined and made easier to qualify. This is often where you will find opportunities for a large portion of qualified research expenses; and

- There are new regulations to clarify the definition of Internal Use Software.

In addition to the federal R&D Tax Credit, over 35 states have an R&D incentive program. These state credits typically follow federal regulations but, have different tax rates and utilization methods. As such, taxpayers can benefit from both federal and state R&D credits to minimize their tax liability and be paid to innovate while growing their local economy.

Qualifications

Qualifications

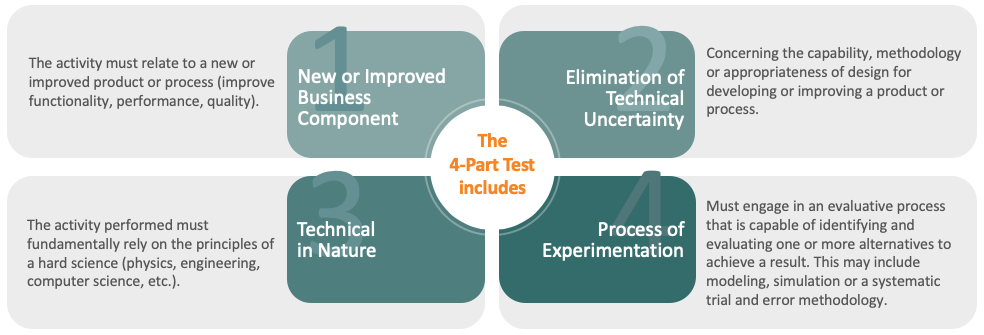

There is a common misconception that R&D only occurs in laboratories of high-tech research facilities, but the definition of R&D activity is quite broad and includes multiple industries and types of activities. The R&D Tax Credit utilizes a four-part test to determine what constitutes a qualified research activity (QRA):

THE FIRST PART OF THE TEST IS THAT THE ACTIVITY MUST RELATE TO A NEW OR IMPROVED PRODUCT OR PROCESS RELATING TO FUNCTION, PERFORMANCE, RELIABILITY, OR QUALITY.

This could be anything from a new formulation for a new or existing product to an improved manufacturing process that improves efficiencies within your manufacturing facility. In an industry fueled by constant innovation and demands from the market, food and beverage companies should have no shortage of these types of activities, referred to as business components.

THE SECOND PART OF THE TEST REQUIRES THE ELIMINATION OF A TECHNICAL UNCERTAINTY

This means the action must be intended to discover information to eliminate uncertainty concerning the capability, methodology, or appropriateness of design for developing or improving a product or process. As a food manufacturer, you have questions or challenges that need to be resolved. It could be whether your facility is even capable of developing a new product idea or improving upon a manufacturing process. More than likely, the uncertainty will revolve around the final design or ideal methodology of a product or process. Your company may have an initial conceptual idea for how to make a new product, but certain constraints or inefficiencies are discovered during development, which lead to changes and improvements to these initial designs and processes. For the food and beverage industry, a prime example is the challenges faced involving regulatory requirements and the many changes needed to ensure compliance or improve shelf-life.

THE THIRD PART OF THE TEST REQUIRE A PROCESS OF EXPERIMENTATION

This means that the taxpayer must engage in an evaluative process capable of identifying and analyzing one or more alternatives to achieve a result. Don’t let this test scare you off by envisioning lab coats and beakers! Although those types of activities certainly constitute a process of experimentation, this test includes anything from modeling and simulation to running trials and testing scale-up methodologies. In other words, this is the work being done to resolve uncertainties. The key here is the evaluation of alternatives:

![]() Did you analyze multiple designs?

Did you analyze multiple designs?

![]() Did you use engineering simulation models to find weaknesses in a design and then improve on that?

Did you use engineering simulation models to find weaknesses in a design and then improve on that?

![]() Did you attempt more than one mixing technique?

Did you attempt more than one mixing technique?

![]() Did you develop multiple prototypes and run those through a series of performance or functional tests to determine a final design or ideal methodology process to manufacture?

Did you develop multiple prototypes and run those through a series of performance or functional tests to determine a final design or ideal methodology process to manufacture?

Maybe your company has a very defined and formal process for new product development like a stage-gate process – a process of experimentation involving various “gates” in the development process where a new product must meet certain parameters before moving into the next stage of development. Or maybe your company has a much less formal and rigid way of developing new products or new processes, and these are no less qualified. For instance, you may have jotted down an idea for a product or process on the back of a napkin, and now you and your team have set about to determine how to bring it to fruition. As you go through your development process, you will certainly evaluate various ways of finding a technical solution. This is your process of experimentation! Trial and error – analyzing a prototype and/or a a methodology and determining if there is a better way.

FINALLY, THE FOURTH PART OF THE TEST REQUIRES THAT THE ACTIVITY PERFORMED MUST BE TECHNOLOGICAL IN NATURE, AND FUNDAMENTALLY RELY ON PRINCIPLES OF CHEMISTRY, PHYSICAL OR BIOLOGICAL SCIENCE, ENGINEERING, ETC.

Finally, the fourth part of the test requires that the activity performed must be technological in nature, fundamentally relying on principles of physical or biological science, engineering, or computer science. This is an easy one. The activities described above must depend on hard science. During your analysis, did you evaluate the physics of your product or look at the biology behind it? Did you test at varying mixing methodologies for optimal viscosity? Maybe you looked at the thermodynamics involved in the process or evaluated your formulation to ensure there would be no microbiological contamination. The examples of qualified scientific principles for this fourth test are endless.

Credits

Credits

So now that we have identified your qualified research activities, how does that translate into Tax Credits? These activities generate qualified research expenditures (QREs) that fall into one of three buckets: wages, supply costs, and contractor costs.

WAGES – this consists of qualified wage expenses, identified through direct wages of technical employees, engineers, or primary research personnel (along with support or supervisory personnel) who affect the research.

SUPPLY COSTS – supplies consist of items used in the qualified activity and prototype component/equipment costs. This would include the materials utilized in the creation of a prototype component part but could also include ingredients used in the development of a new formulation during the evaluation of various alternatives. There is also the possibility of taking equipment costs for equipment purchased and modified specifically for the development of a new manufacturing product or process.

CONTRACTOR COSTS – these are comprised of payments made to a third party to perform qualified research along with fees paid to consultants or engineering firms. An example in the food and beverage industry would be any costs associated with utilizing a third party to provide certain tests on a new product or equipment as required by a regulatory body.

Additionally, if an outside party is building fixtures for the manufacture of a new product (or as part of a new process), these costs could also be taken as either a supply or contractor cost, depending on the work.

About ABGi

Business leaders choose ABGi as their tax incentive specialist because, for over 30 years, our expertise has allowed us to maximize their credits and deductions, decreasing tax liability the way the government intended. Our approach to work minimizes business disruption and produces high-quality, compliant work.

Contact us today!